At OEDS, we collaborate with our clients to develop world-class, durable, next-generation products from front end innovation to production implementation with a full suite of product development services.

Development of new products, devices and equipment from concept to production launch.

Our core services focus on the design and development of products for our clients that have a level of technical sophistication. Our mission is to help our customers to drive growth by innovating and launching successful new products in rapid timeframes in competitive business environments.

CONCEPT TO PRODUCTION

At ODES our team has extensive experience with the full product development process from kick-off to market launch, including:

- interviewing end users in their environment

- creative brainstorming (white space / blank sheet)

- applying new technologies

- proof-of-concept prototyping

- aesthetic design / styling

- creating world-class ergonomic designs

- engineering design of complex systems

- high quality and reliability

- engineering testing and reliability

- production launch and approval

- market feedback and continuous improvement

OEDS provides solutions to companies of all sizes with the expertise, experience and network of contacts to develop revolutionary world-class products.

STRUCTURAL SKID DESIGN

We offer a full service that includes industrial building and machinery foundation design, as well as new building structure design, including machinery supports, custom structures, and foundations. Engineering and Feasibility Studies related to improvements and maintenance of existing building structures and foundations are also available. We can assist you in implementing repair and improvements to your buildings and structures.

- Building Structures

- Machine Support Structures

- Machine Foundations

- Pressure Vessel Analysis

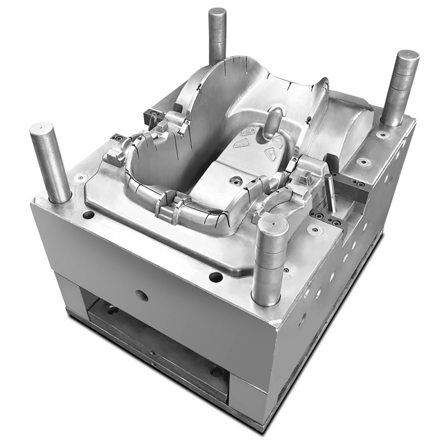

MOULD DESIGN

We Provide The Best Design Solution For Your Mould And Die Design Requirement.

One Of The Most Common Methods Of Converting Plastics From The Raw Material Form To An Article Of Use Is The Process Of Injection Moulding. This Process Is Most Typically Used For Thermoplastic Materials Which May Be Successively Melted, Reshaped And Cooled. Injection Moulded Components Are A Feature Of Almost Every Functional Manufactured Article In The Modern World, From Automotive Products Through To Food Packaging. This Versatile Process Allows Us To Produce High Quality, Simple Or Complex Components On A Fully Automated Basis At High Speed With Materials That Have Changed The Face Of Manufacturing Technology Over The Last 50 Years Or So.

We Are Specialized In

- Injection Mould Design

- Sand Casting Die Design

- Gravity Die Casting

- Pressure Die Casting Design(PDC, LPDC)

- Press Tool

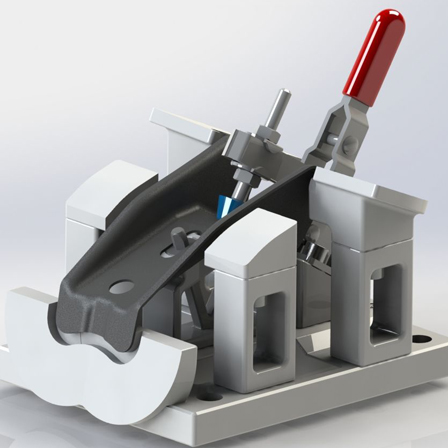

JIGS AND FIXTURE

We provide jigs and fixture design services. These services are being provided by highly experienced designers who will help you with an efficient design which will reduce your production cost. We design these for industries like Automotive OEMs & Automotive Ancillaries, Aerospace and Manufacturing etc

We design following types of Jigs and Fixtures:

- Assembly fixtures

- Hydraulic and Pneumatic fixtures

- Checking fixtures and check gauges

- Testing fixtures

- Welding and Machining fixtures

- Woodworking jigs and framing jigs

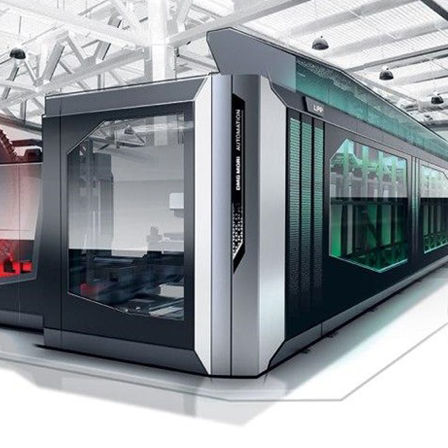

MACHINE DESIGN

We provide mechanical design services to manufacturers of machinery through our expertise in developing digital design to reduce engineering lead time and thus keeping the businesses productive and profitable.

For Machine Building industry, we offer a) Conceptual sketches to 3D model, b) Detailed drawing c) Reverse Engineering d) Structural, Thermal and Vibration Analysis (FEA), Kinematic (mechanisms) Analysis etc.

In machine design, the designer’s task is to determine the motion, forces and energy transfer involved so as to determine the sizes, shapes and materials for each element of the machine. When any component of machine ceases to perform its intended function, machine element or machine is said to have failed. Generally the machine elements are designed on the basis of strength and rigidity so that they are able to withstand the applied load with permissible deformation or stress. In addition to strength and stiffness, other factors that are considered in design of machine element are weight, cost, wear, safety, reliability etc.